What is Deep Drawn Metal Stamping?

Stamping is a general term that encompasses a broad range of metal forming capabilities and industrial uses.

Parts produced by metal stamping can range from 0.25 inches in diameter or smaller, to very large aircraft, automotive and appliance parts.

Sometimes referred to as metal pressing, it is classified as a cold forming or cold working process, meaning it is usually done at room temperature. See more information on how metal drawing works, applications and benefits.

The Deep Drawn Stamping Process

Although it can be modified to manufacture particular parts, our deep drawn stamping process typically follows the same five steps:

- Design Review: Our engineers review the part design in detail to ensure it is appropriate for deep drawn stamping. This includes in-depth analysis of component dimensions, materials, draw ratio, and required tolerances.

- Press Selection: Our engineers determine which machine size and caliber will be best suited for the part dimensions and material.

- 3D Virtual Prototyping: A prototype of the part is created using virtual software. The prototype is run through numerous operational simulations to catch any design problems before the production process begins.

- Equipment Setup: Our skilled engineers review the component dimensions and requirements and set up the die and punch.

- Deep Draw Process: The sheet metal, or metal blank, is placed on the die and secured. The press is then activated to force the punch against the die with up to 400 tons of force. The process is repeated until the component achieves the desired size and shape.

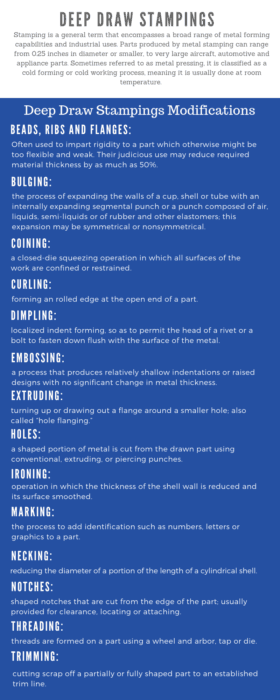

Deep Draw Stampings Modifications

This form of stamping usually involves other forming operations to complete the part such as:

Beads, Ribs, and Flanges: often used to impart rigidity to a part that otherwise might be too flexible and weak.

Their judicious use may reduce required material thickness by as much as 50%.

Bulging: the process of expanding the walls of a cup, shell or tube with an internally expanding segmental punch or a punch composed of air, liquids, semi-liquids or of rubber and other elastomers; this expansion may be symmetrical or nonsymmetrical.

Coining: a closed-die squeezing operation in which all surfaces of the work are confined or restrained.

Curling: forming a rolled edge at the open end of a part.

Dimpling: localized indent forming, so as to permit the head of a rivet or a bolt to fasten down flush with the surface of the metal.

Embossing: a process that produces relatively shallow indentations or raised designs with no significant change in metal thickness.

Extruding: turning up or drawing out a flange around a smaller hole; also called “hole flanging.”

Holes: a shaped portion of metal is cut from the drawn part using conventional, extruding, or piercing punches.

Ironing: operation in which the thickness of the shell wall is reduced and its surface smoothed.

Marking: process to add identification such as numbers, letters or graphics to a part.

Necking: reducing the diameter of a portion of the length of a cylindrical shell.

Notches: shaped notches that are cut from the edge of the part; usually provided for clearance, locating or attaching.

Threading: threads are formed on a part using a wheel and arbor, tap or die.

Trimming: cutting scrap off a partially or fully shaped part to an established trim line.

Benefits of Deep Drawn Stamping

Deep drawn stamping offers numerous advantages over other metal forming processes. Punch presses are designed to operate at high speed and can be equipped with automatic material feeds for enhanced efficiency. In fact, deep drawn stamping is one of the quickest manufacturing methods for high-volume production.

Deep drawn components are also created in one piece, thereby reducing the need for additional assembly. This has the added benefit of seamless construction, which is ideal for waterproof or airtight applications.

Deep drawn stamping is highly versatile and can be used to create complex, detailed components with an exceptional degree of accuracy and repeatability. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression exerted on the metal during the forming process. The fundamental structure of deep drawn metals is often highly compressed into a very hard crystalline structure.

Applications Spotlight

At Hudson Technologies, we are pleased to offer deep drawn stamping solutions for customers in a variety of industries and applications. Our stamping expertise ranges from battery enclosures and medical device components to metal diaphragms.

Battery Enclosures

Our deep drawn battery enclosures can be manufactured to house batteries in many industries, including aerospace, mining, energy storage, medical devices, and even hybrid vehicles. With seamless construction, quality surface finishes, and precise measurements, our battery enclosures protect sensitive battery components from hazardous conditions.

Medical Device Components

We offer deep drawn stamping services for an array of implantable medical devices. Our seasoned experts will help you conceptualize, design, and manufacture precision medical components down to the smallest detail.

Metal Diaphragms

We are pleased to provide expert consultation and manufacturing services for metal diaphragms used in many different industries. We are well versed in the varied and complex needs of pressure sensing and regulatory applications in food and beverage, pharmaceutical, manufacturing, oil and gas, and laboratory operations.

Considerations for Deep Drawn Stamping

When considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following:

- Reduced Material Waste: Deep drawn stamping uses a greater amount of the base material than other metal forming processes for significantly reduced material waste.

- Measurement Is Critical: Not only is it important to ensure that the die dimensions are accurate, it is equally essential to consider the material thickness and desired measurements. Incorrect measurements can result in thin walls and inaccurate dimensions.

- Draft and Tapering: Due to the fundamental manufacturing process of deep drawn stamping, some draft and tapering of the top of the component is unavoidable. This should be taken into consideration during the initial design phase.

- Varied Material Thickness: Deep drawn components will typically have varying thickness with thinner walls and a thicker base. This can be mitigated by tooling after the drawing process is completed.

Manufacturing Components Using Deep Drawn Stamping

Our comprehensive guide overviews all of the considerations you need to take into account when creating deep-drawn stamped components.

Deep Drawn Metal Components from Hudson Technologies

At Hudson Technologies, we specialize in drawn metal cases in a wide range of materials and shapes. Sizes range from 0.125 to 12.0 inches wide, and up to 12.0 inches deep. Browse our catalog to view our wide array of standard shapes and sizes, or learn more about creating custom components.