Farley is the grandson of Hudson’s founder Charles Batka. He has been employed at Hudson for 40 years. Farley started his career as an apprentice toolmaker and eventually became a Department Supervisor, Business Unit Manager for automotive stampings and drawn components, Tool Room Manager, quoting and estimating and now Sales Engineering.

Farley has extensive knowledge of the deep draw process, materials, heat treating (annealing), as well as secondary operations to deep drawn components (finishes, modifications, brackets, inserts, etc.

Select one of the questions below, or ask your own!

General

- What are the advantages of using deep drawn components?

- What is deep draw?

- What metals can be deep drawn?

- Deep draw technical considerations

- Can deep drawn components be modified?

- What are DFARs, RoHS and REACH Requirements?

- What is the description of visual and cosmetics characteristics found in deep drawn parts?

- What is Hudson’s position on purchases from Kobe Steel?

What are the advantages of using deep drawn components?

To be considered deep drawn, the height of the case is usually at least two times the diameter. Deep drawn cases are used to enclose technology, especially in demanding environments or whenever tight tolerances and reliability are important.

The deep draw process starts when a flat piece of metal, called a blank or disc, is placed over a cavity called a die. A punch then forces the metal through the die, forming it into a shape.

These precision punches and dies are known as tooling. The tooling is set up in power presses which produce the tonnage, or energy, needed to force the material through the draw process.

During the draw process the material moves into the shape of the die. The flow of material is controlled through pressure applied to the blank and lubrication applied to the die or the blank.

Each draw operation is a separate step and each step reduces the diameter and increases the height of the part. It may take five or more draws, also called reductions, to achieve the final shape.

Many factors, including material type and thickness, corner and bottom radii, and shape, determine the number of reductions required to make an enclosure.

Below is an infographic that outlines the different deep draw stamping modification that we can manufacture:

More information about deep drawn stamping.

What is deep draw?

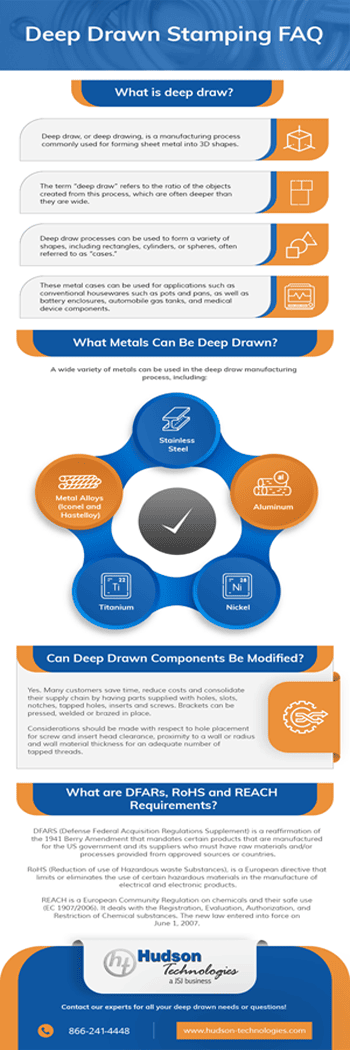

Deep draw, or deep drawing, is a manufacturing process commonly used for forming sheet metal into 3D shapes. The term “deep draw” refers to the ratio of the objects created from this process, which are often deeper than they are wide. Deep draw processes can be used to form a variety of shapes, including rectangles, cylinders, or spheres, often referred to as “cases.” These metal cases can be used for applications such as conventional housewares such as pots and pans, as well as battery enclosures, automobile gas tanks, and medical device components.

Learn more about the deep draw manufacturing process.

What metals can be deep drawn?

A wide variety of metals can be used in the deep draw manufacturing process, including stainless steel, aluminum, nickel, and titanium. Metal alloys, such as iconel and hastelloy, are made from a combination of base metals and can provide unique combinations of heat resistance, formability, and strength-to-weight ratios.

Learn more about materials used in deep draw metal manufacturing.

What technical considerations should I keep in mind when making deep draw components?

Many factors influence success or failure when considering a deep drawn case as an enclosure solution.

Deep drawn components can offer significant material cost saving over machined parts. While turned parts often retain less than 50% of the originating stock, the deep drawn process typically retains closer to 85%.

When exploring non-round shapes such as squares and rectangles, the inside corner and bottom radii are two of the most important factors to consider. Generally, there is a relationship between the desired material thickness and the requested corner radii.

The general rule is the material thickness times two, equals the smallest corner radius obtainable (larger corner radii are desirable and may reduce the amount of draws). Exceptions can be made with additional draw operations to further reduce the corner radii. Caution statement – increased material thinning and adjacent sidewall bow can occur in some cases.

Draft or taper are inherent to drawn cases. A small amount of draft is necessary in order for the case to strip off of the punch after the draw operation. This will render the can slightly smaller on the closed end inside and larger on the open end inside. Our standard draft is .001″ (.025mm) per inch of length.

Drawn cases also tend to have different material thicknesses throughout their length. The bottom of the can (closed end) is generally thicker than the sidewalls. Some materials have a tendency to thin or stretch more than others.

In some cases, depending on the particular requirements, the tooling may be designed to intentionally thin or “iron” the sidewalls beyond the natural tendency. This may add more dimensional stability and a produce a more aesthetically pleasing case.

Burrs occur whenever metal is cut, trimmed or pierced. A burr can be discussed as displaced, attached material beyond the flat plane that is perpendicular to that surface.

This is a result of the shearing and subsequent break of the material during the cutting/piercing process. Burr height and direction can be controlled with tooling clearances and punching direction. Our standard burr height is 10% of the pierced material thickness unless otherwise requested. Burrs can be removed through additional mechanical or chemical processes.

Work hardening, or cold working of material during the deep draw process, must be relaxed through a heatreat process known as annealing. This process occurs as an intermediate step during the forming and case reduction sequence.

Annealing is a specific temperature and atmospheric environment designed to relieve stress created from cold working. Each metal type has a unique recipe of time, temperature, atmosphere, and cool down rate.

Atmosphere refers to the gaseous environment used in a vacuum or forced flow furnace. Common atmospheres are Hydrogen, Nitrogen and Argon. Selected gases generally prevent oxidation of the parts and provide an intergranular cleansing.

Due to the criticality of the annealing process, Hudson Technologies heat treats its parts in-house when applicable.

Can deep drawn components be modified?

Yes. Many customers save time, reduce costs and consolidate their supply chain by having parts supplied with holes, slots, notches, tapped holes, inserts and screws. Brackets can be pressed, welded or brazed in place.

Modifications can be performed using hard tooling or milling, and drilling equipment.

Considerations should be made with respect to hole placement for screw and insert head clearance, proximity to a wall or radius and wall material thickness for an adequate number of tapped threads.

Hudson Technologies can also provide cases with paint, powder coated, silk-screened graphics and various plating types.

All we need is a drawing or sketch with dimensions and tolerances and we can quote the appropriate tooling or process.

More details can be found in Core Capabilities and Deep Drawn Stamping.

What are DFARs, RoHS and REACH requirements?

DFARS (Defense Federal Acquisition Regulations Supplement) is a reaffirmation of the 1941 Berry Amendment that mandates certain products that are manufactured for the US government and its suppliers who must have raw materials and/or processes provided from approved sources or countries.

This is important information to provide when requesting a quote to ensure that our raw material source choices are compliant to this requirement.

RoHS (Reduction of use of Hazardous waste Substances), is a European directive

that limits or eliminates the use of certain hazardous materials in the manufacture of electrical and electronic products.

Some raw materials and plating types fall under restriction of use to this directive. This is important information to provide when requesting a quote so that the proper research is performed and alternatives can be offered to remain compliant.

REACH is a European Community Regulation on chemicals and their safe use (EC 1907/2006). It deals with the Registration, Evaluation, Authorisation and Restriction of Chemical substances. The new law entered into force on 1 June 2007. Hudson Technologies‘ products are REACH compliant.

What is the description of visual and cosmetics characteristics found in deep drawn parts?

Cosmetics: The nature of the deep draw process can leave minor cosmetic imperfections on the cases. Minor scratches on the inside and outside that show no measurable material displacement would be considered acceptable.

Small surface dings or tool repair marks, including raw material flaws would be a reasonable expectation. Slight scuffing, burnishing and surface appearance changes on any given surface are considered normal conditions.

Cleanliness: Every effort is made to remove the manufacturing lubricants and processing contamination. Cleanliness would be described as free from residual oils, particles, and tack free. Surface staining or minor discoloration from rinse cycles including water deposits are normal.

Cold Rolled Steel: Plain steel parts tend to rust quickly after fabrication. All efforts are made to reduce rust including intermediate application of rust preventing solutions. A slight brown/red discoloration of the material is considered normal. We will not ship rust pitted parts.

If any of the above conditions are not acceptable to your process or requirements we can, upon request, develop the manufacturing and handling process to ensure compliance to the request. Hudson Technologies can provide a quote for this service.

What is Hudson’s Position on Purchases from Kobe Steel?

ccording to recent news reports, Kobe Steel allegedly falsified raw material tests certifying the production specifications of their aluminum and copper products from September 2016 through August 2017.

Hudson Technologies has not purchased any raw material from Kobe Steel, either directly or indirectly from other raw material processors that show Kobe Steel as the originating mill. We have extensive traceability for all raw material used to manufacture our products, including the disclosure of the originating mill.