Metal Injection Molding (MIM) vs. Deep Drawn Stamping (DDS)

Leave a CommentCreating industry-defining metal components starts by forging raw metal into the ideal shape and size. Fortunately, there are a wide variety of techniques available to help you create high-performing metal components. It can be challenging to decide which method works best for your project. Each type of metal forming offers unique advantages and disadvantages, and no one technique is perfect for every project.

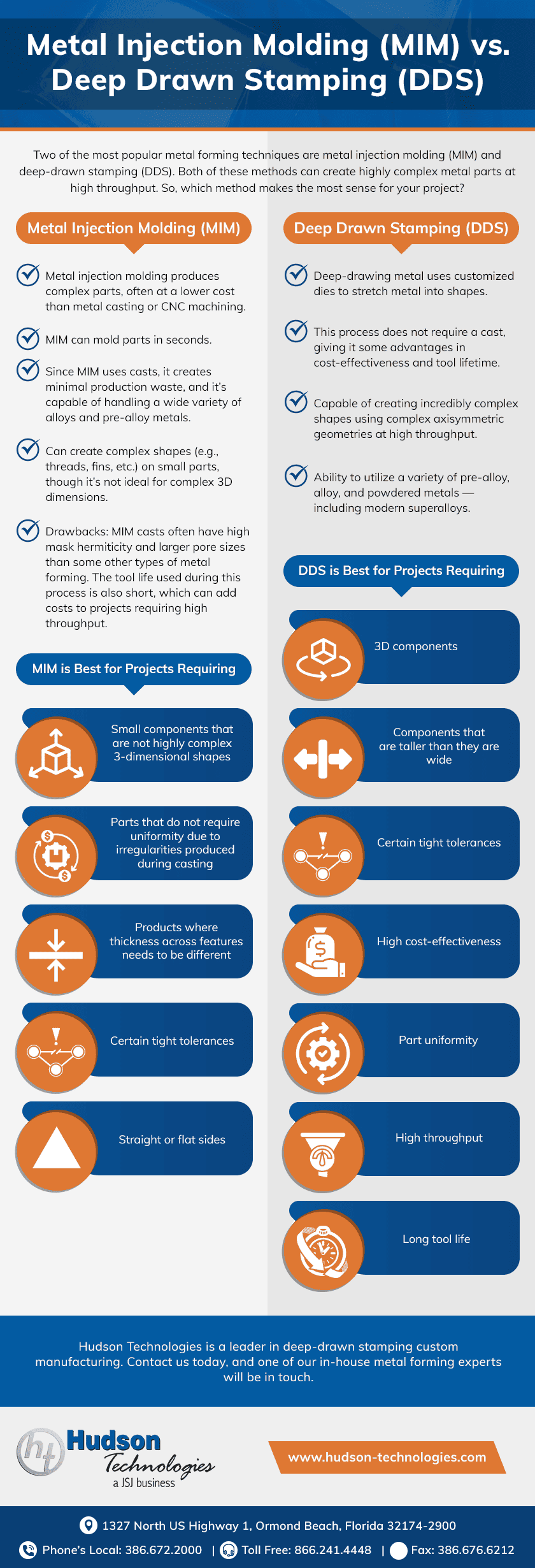

Two of the most popular metal forming techniques are metal injection molding (MIM) and deep-drawn stamping (DDS). Both of these methods can create highly complex metal parts at high throughput. So, which method makes the most sense for your project?

Metal Injection Molding (MIM) vs. Deep Drawn Stamping (DDS)

Metal forming processes shape metal components without changing their volume, allowing manufacturers and suppliers to create a variety of metal tools, instruments, and parts. Two of the most common types of metal forming — metal injection molding and deep drawn stamping — offer unique advantages and disadvantages, depending on the project.

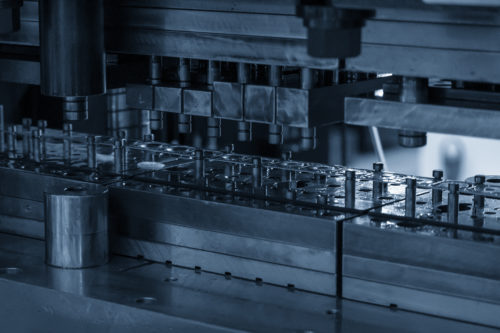

Metal injection molding produces complex parts, often at a lower cost than metal casting or CNC machining. Once a cast is made, MIM can mold parts in seconds. Since MIM uses casts, it creates minimal production waste, and it’s capable of handling a wide variety of alloys and pre-alloy metals. Importantly, metal injection molding can create complex shapes (e.g., threads, fins, etc.) on small parts, though it’s not ideal for complex 3D dimensions. However, there are also drawbacks. MIM casts often have high mask hermiticity and larger pore sizes than some other types of metal forming. The tool life used during this process is also short, which can add costs to projects requiring high throughput.

Deep-drawing metal uses customized dies to stretch metal into shapes. This process does not require a cast, giving it some advantages in cost-effectiveness and tool lifetime. DDS is also capable of creating incredibly complex shapes using complex axisymmetric geometries at high throughput. Another advantage of deep-drawn stamping is its ability to utilize a variety of pre-alloy, alloy, and powdered metals — including modern superalloys.

Choosing Between MIM and DDS

Both metal injection molding and deep-drawn stamping have advantages and disadvantages. The type of alloy you use, the technical requirements of your project, and your throughput requirements all play a role in deciding between these two metal forming options.

MIM is best for projects requiring:

- Small components that are not highly complex 3-dimensional shapes

- Parts that do not require uniformity due to irregularities produced during casting

- Products where thickness across features needs to be different

- Certain tight tolerances

- Straight or flat sides

MIM is not ideal for projects requiring:

- 3D products

- Identical components at high throughput

- Certain tolerances

- High repeatability

- Low porousness

DDS is best for projects requiring:

- 3D components

- Components that are taller than they are wide

- Certain tight tolerances

- High cost-effectiveness

- Part uniformity

- High throughput

- Long tool life

DDS is not ideal for projects requiring:

- Perfectly straight edges

- Low volume runs or low-cost prototyping

- Certain tolerances

Hudson Technologies’ 2022 Strategy

Hudson Technologies is a leader in deep-drawn stamping custom manufacturing. We provide end-to-end DDS solutions, and we specialize in helping you convert projects using non-ideal metal forming into deep-drawn stamping. Our range of cutting-edge machinery and technology allows us to tackle complex projects using best-of-breed deep-drawn stamping techniques. From drawing and sampling to design, we’re ready to help you accomplish your next high-volume production project.

Contact us today, and one of our in-house metal forming experts will be in touch.

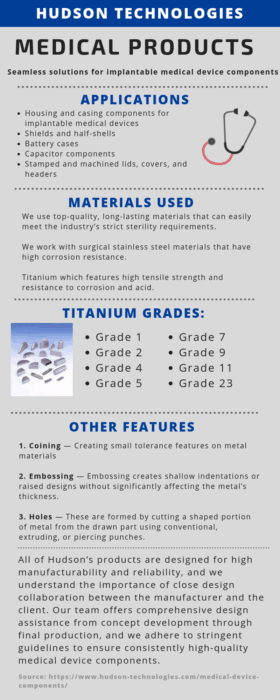

Metal components serve a vital role in the construction of medical devices, which must be highly precise, durable, and biocompatible for both internal and external use. Due to its immense versatility, metal stamping allows the medical industry to create and refine these devices quickly and efficiently.

Metal components serve a vital role in the construction of medical devices, which must be highly precise, durable, and biocompatible for both internal and external use. Due to its immense versatility, metal stamping allows the medical industry to create and refine these devices quickly and efficiently. All permanently implanted medical devices, including pacemakers, cochlear devices, internal defibrillators, and drug pumps, are manufactured from titanium. Titanium is the only metal that the human body will not reject. Hudson has a long history of deep-drawing titanium into intricate shapes and has been manufacturing implantable titanium medical components since the early 1970s.

All permanently implanted medical devices, including pacemakers, cochlear devices, internal defibrillators, and drug pumps, are manufactured from titanium. Titanium is the only metal that the human body will not reject. Hudson has a long history of deep-drawing titanium into intricate shapes and has been manufacturing implantable titanium medical components since the early 1970s. Stainless Steel Type 201/201L

Stainless Steel Type 201/201L Stainless steel type 316 is distinguished by its higher nickel and molybdenum content. Type 316 exhibits extreme resistance to corrosion and moisture in comparison with other stainless steel alloys but is also more expensive due to its high nickel content. It holds up particularly well to salt water and chlorides, which makes it useful for marine components, stainless steel floats, and medical devices.

Stainless steel type 316 is distinguished by its higher nickel and molybdenum content. Type 316 exhibits extreme resistance to corrosion and moisture in comparison with other stainless steel alloys but is also more expensive due to its high nickel content. It holds up particularly well to salt water and chlorides, which makes it useful for marine components, stainless steel floats, and medical devices. Stainless steel 409 is a temperature-resistant blend of stainless steel with a higher iron content. This ferritic stainless steel contains 11% chromium, which provides good corrosion resistance. However, its greatest benefit lies in its ability to withstand extremely high temperatures. Although Type 409 exhibits a greater level of corrosion-resistance than coated iron alloys, it is less resistant than most other stainless steels. Light rust may eventually form with extended exposure to moisture or corrosive elements.

Stainless steel 409 is a temperature-resistant blend of stainless steel with a higher iron content. This ferritic stainless steel contains 11% chromium, which provides good corrosion resistance. However, its greatest benefit lies in its ability to withstand extremely high temperatures. Although Type 409 exhibits a greater level of corrosion-resistance than coated iron alloys, it is less resistant than most other stainless steels. Light rust may eventually form with extended exposure to moisture or corrosive elements. Pure Titanium

Pure Titanium