History of Titanium and Its Applications

Leave a CommentThe history of titanium stretches way back to 1791 when it was discovered by a pastor in Cornwall, England. However, it wasn’t until 1910 that it became prominent on the manufacturing scene when metallurgist Matthew A. Hunter began producing it in the United States. As the ninth most abundant element on earth, it can be found […]

The Advantages and Process of Forming Deep-Drawn Aluminum Parts

Leave a CommentAluminum’s properties grant it many advantages that differentiate it from other metals. Aluminum is versatile, sustainable, and recyclable, and it’s only about one third of the weight of steel. Deep-drawn aluminum parts are becoming more and more popular among manufacturers and customers alike. Some benefits associated with deep-drawn aluminum include: The ability to be used in […]

Tags: deep draw

Applications of Different Processes

Leave a CommentMetal finishing refers to the process of coating metallic parts with a thin metal coating. Metal finishing is an umbrella term, covering processes that include: Cleaning Polishing Plating Buffing Brushing Grinding Vibratory finishing Many metal finishing processes rely on the use of electroplating, during which metal ions are deposited onto a substrate via an electric […]

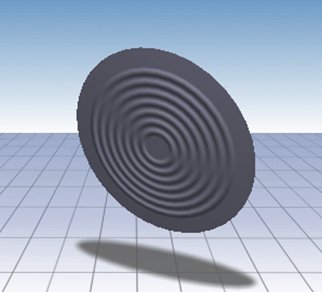

The Two Main Types of Solid Center Metal Diaphragms and How They’re Different

Leave a CommentMetal diaphragms are specially engineered components that fulfill several critical roles across many industries. Generally nothing more than thin, circular plates, diaphragms help regulate pressure levels in complex machinery systems. What renders these plates so critical to countless processes is their ability to change their shapes as needed. Diaphragms undergo elastic deformation when subjected to […]

Tags: metal diaphragms

Farley’s Top Five Things to Know for Deep Draw Metal Stamping

Leave a CommentThe deep draw process itself begins once a flat piece of metal – referred to as a blank or a disc – is placed over a cavity known as a die. A punch pushes the metal through the die to form it into the specific shape required by the design. Deep drawn metal stamping has […]

How Our Partners Help Us Grow

Leave a CommentOver the years, Hudson Technologies has established itself as a leading supplier of metal shaping services for clients across the U.S. We provide top-quality engineering services and technical support for all kinds of metal fabrication needs, whether we’re deep-draw forming aluminum alloys for aerospace manufacturers or we’re stamping titanium parts for medical devices. We’ve worked […]

Battery Enclosures for Military Applications

Leave a CommentBatteries form critical components of many active weapon systems in military and defense projects. Because batteries contain toxic substances and must be kept in working condition, defense contractors are turning to battery enclosures as a crucial means to preserve the health of their systems. Keeping the batteries enclosed and protected ensures optimal performance, reliability, and safety. […]

A New Generation of Pickup Covers

Leave a CommentLace Music Productions, a division of Actodyne General, Inc., was founded in 1979 by Don Lace, Sr. Don had extensive experience in high intensity lighting, speakers, and magnetics, and an early focus of Don’s was designing and manufacturing solenoids. Coil winding was at the heart of his business. In 1967 his path crossed with Fender Musical […]

Industries Driving Metal Stamping Growth

Leave a CommentThe metal stamping industry is driven by the combined market demands of several important industries. Aerospace and military-grade technologies, fueled by precision metal stamping, are continually advancing, and the transportation industry simply wouldn’t exist without metal stamping manufacturing for the automotive and oil and gas industries. Aerospace and Defense Metal-stamped parts are used widely in […]

Platarg Transfer Press Announcement

Leave a CommentHudson Technologies – a leader in deep drawn metal enclosures, stampings, and cases for the past 75 years – recently invested in a Platarg Transfer Press as part of our continuing efforts to provide our customers with the latest in state-of-the-art technology and solutions. Options for Deep-Drawing at Hudson To shape a deep-drawn part in […]