Metal Enclosures, Cases and Covers

Metal enclosures are ubiquitous in the industry, with common examples including cable enclosures, panel enclosures, wiring enclosures, and industrial electrical boxes. Larger metal box enclosures are also common, including equipment enclosures for sensitive machinery. In all of these cases, these metal cases serve to protect small and large parts from environmental exposures, keeping electronics or other system components in working order for their entire lifespan.

As a leading U.S. manufacturer of deep-drawn stamped components, Hudson Technologies is proud to offer turnkey manufacturing services for custom metal enclosures. We work with applications ranging from general manufacturing to medical, military, and oil and gas, in each case choosing the ideal materials, stamping, and finishing techniques to suit our client’s unique needs.

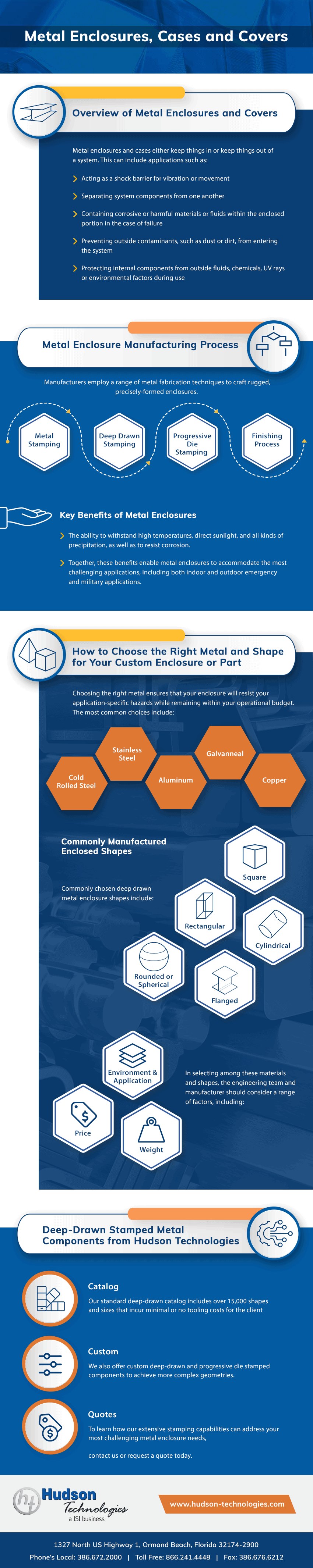

Overview of Metal Enclosures and Covers

Click to Expand

Metal enclosures are solid metal cases or covers that are carefully engineered and manufactured to suit a particular application. The components are most often used to surround and protect critical components. They’re often used such as shielding expensive equipment from the elements or anywhere where moisture or contaminants are a concern. Alternatively, some metal enclosures perform the opposite function, containing the internal components of a system so that they don’t leak into the environment or into adjacent compartments.

To best protect their contents, industrial metal enclosures vary significantly depending on their application. For instance, metal enclosures may be small enough to encapsulate a battery, or big enough to cover a large piece of machinery. Similarly, their shape depends on the shape of the equipment to be protected. Enclosures are commonly square, rectangular, or cylindrical, although custom shapes are also available to conform to unusual geometries. In all cases, the most effective enclosures are customized to the appropriate dimensions and systems, ensuring that they are exactly the right size for their application without wasting unnecessary space.

When engineered appropriately, metal cases and enclosures keep dust, moisture, and chemicals from harming sensitive machinery, while also preventing pollutants from escaping into the environment. As a result, they are highly valued across industries, especially in those with extreme conditions and expensive or sensitive system equipment.

To summarize, metal enclosures and cases either keep things in or keep things out of a system. This can include applications such as:

- Acting as a shock barrier for vibration or movement

- Containing corrosive or harmful materials or fluids within the enclosed portion in the case of failure

- Preventing outside contaminants, such as dust or dirt, from entering the system

- Protecting internal components from outside fluids, chemicals, UV rays or environmental factors during use

Metal Enclosure Manufacturing Processes

Metal enclosures are engineered to be customized to their applications, as the manufacturing processes involved to create them. Manufacturers employ a range of metal fabrication techniques to craft rugged, precisely-formed enclosures.

Industrial Applications of Metal Enclosures and Shapes

Metal enclosures are useful in virtually any industry that employs sensitive or expensive equipment, whether it be batteries, electrical systems, or drilling equipment. The right metal enclosure protects these systems from dirt, contaminants, and fluids, preserving their functionality and preventing downtime. Industrial enclosures similarly prevent dust buildup that can reduce product quality and interfere with proper equipment function over time. Secure, well-fitted metal enclosures are the best way to minimize these risks and keep systems at optimal performance.

Industries that often employ custom enclosures to protect their electronics include:

- Food and beverage

- Solar battery storage

- Pharmaceutical processing

- Automotive manufacturing

- Electronics

- Industrial machinery

- Medical

- Printing

Key Benefits of Metal Enclosures

Metal enclosures offer a number of key advantages over plastic or glass casings. These include the ability to withstand high temperatures, direct sunlight, and all kinds of precipitation, as well as to resist corrosion. At the same time, the combination of seamless stamping processes and annealing treatments grant metal enclosures higher strength and better resistance to shock and vibration. Together, these benefits enable metal enclosures to accommodate the most challenging applications, including both indoor and outdoor emergency and military applications.

How to Choose the Right Metal and Shape for Your Custom Enclosure or Part

To experience the maximum benefit from a metal enclosure, it’s important that clients work with manufacturers to select the right materials. Choosing the right metal ensures that your enclosure will resist your application-specific hazards while remaining within your operational budget. The most common choices include:

- Cold rolled steel

- Stainless steel

- Aluminum

- Galvanneal

- Copper

Commonly Manufactured Enclosure Shapes:

Depending on the application, the shape the enclosure is engineered to become is critical for its end performance. For example, a battery cover might be slightly larger than the battery itself to create space for fluid leakage, wires, or sensors.

Commonly chosen deep drawn metal enclosure shapes include:

- Square

- Rectangular

- Rounded or spherical

- Cylindrical

- Flanged

In selecting among these materials and shapes, the engineering team and manufacturer should consider a range of factors, including:

- Environment and Application. The most critical factor that impacts material selection is the setting in which an enclosure will be used. The ideal metal for an outdoor enclosure must resist precipitation, changing temperatures, and UV light, while one used in a pharmaceutical facility should be corrosion-resistant and easy to sterilize. These factors determine which metals will perform well in your application either on their own or after finishing.

- Many cost-effective metals function perfectly well in industrial environments, especially in indoor general manufacturing settings. Additionally, the application of coatings and finishing processes can enhance a more affordable metal’s performance with minimal impact on the component’s price. While some extreme environments may require more expensive alloys, most clients with budgetary constraints have many options.

- Weight. Different metals have different densities and strength-to-weight ratios, meaning that two metals with the same performance characteristics can have very different weights. Clients should be aware of how much weight a specific metal will add to their equipment, both alone and when full. Manufacturers may recommend lighter metals when developing very large enclosures, or those that will be installed above ground level. Aluminum electronics enclosures, for instance, tend to offer similar strength to steel enclosures at a lower weight.

Industry Spotlight: Oil & Gas Enclosures

One industry that relies heavily on metal enclosures is the oil and gas industry. Electrical systems used at drilling sites, refineries, and similar facilities are often exposed to corrosive chemicals, extreme temperatures, and moisture, including saltwater spray. Consequently, it’s absolutely critical that facility managers protect sensitive circuitry to avoid workplace hazards or costly downtime. Metal enclosures offer a tight seal against all of these environmental exposures while also resisting damage from vibration or shock. This keeps electrical systems running properly, no matter how tough the environment.

Oil and gas industry clients use a full range of metal enclosures to maximize uptime and protect their employees. These include wall-mounted, floor-mounted, and free-standing cases, as well as junction boxes and troughs. Especially popular are stainless steel enclosures, which offer a favorable combination of strength and corrosion resistance to chemicals and saltwater. Whether your facility is downstream, upstream, or midstream in the oil and gas industry, custom metal enclosures can help you maintain a safe and efficient working environment.

Deep-Drawn Stamped Metal Components from Hudson Technologies

Hudson Technologies is a trusted supplier of deep-drawn stamped components and shapes of all types, including custom metal enclosures for a full range of industry applications. Our design team works one-on-one with clients to offer fully customized solutions, no matter how unusual or complex the application requirements. That commitment, combined with our extensive capabilities and industry experience, allows us to meet the most demanding metal enclosure needs.

Our standard deep-drawn catalog includes over 15,000 shapes and sizes that incur minimal or no tooling costs for the client. However, we also offer custom deep-drawn and progressive die stamped components to achieve more complex geometries. These components are available in an array of high-performance metal alloys ideal for protective electronics enclosures, including stainless steel, aluminum, titanium, and cold-rolled steel.

To learn how our extensive stamping capabilities can address your most challenging metal enclosure needs, contact us or request a quote today.

Facilities List

Hudson Technologies houses machines built to meet your specific needs.