Metal Stamping FAQs

Select from the questions below.

General

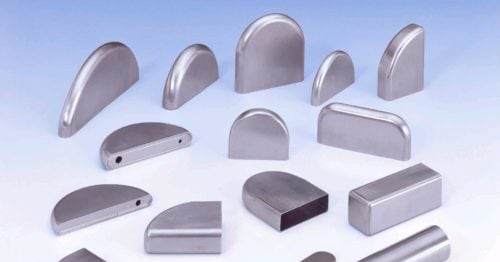

- What are the advantages of using deep drawn components?

- What is deep draw?

- What metals can be deep drawn?

- Deep draw technical considerations

- Can deep drawn components be modified?

- What are DFARs, RoHS and REACH Requirements?

- What is the description of visual and cosmetics characteristics found in deep drawn parts?

- What is Hudson’s position on purchases from Kobe Steel?

Standard (Catalog) Products

- What is the catalog or standard part number nomenclature?

- Why is the Hudson part number sometimes different on a part I have not ordered in a long time?

- Do you have a minimum lot charge?