With many manufacturing methods available, it can be difficult to choose the best option for your project. In this blog, we will compare progressive die stamping to various other methods to help you determine if this technique is the most suitable choice for manufacturing your components.

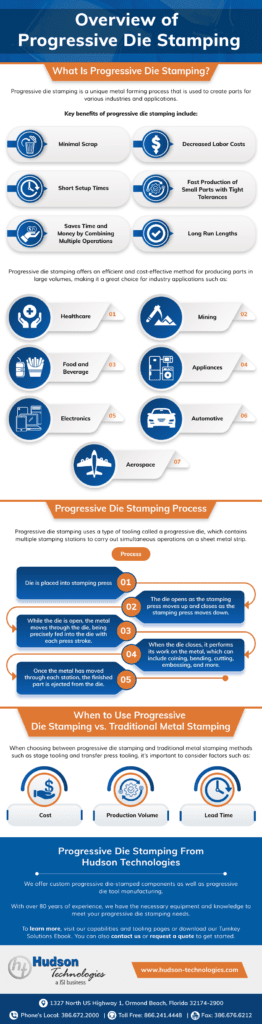

What is Progressive Die Stamping?

Progressive die stamping is a unique metal forming process that is used to create parts for various industries and applications. This type of metal stamping incorporates various work stations, each of which carries out different operations on the part. Key benefits of progressive die stamping include:

- Minimal scrap

- Decreased labor costs

- Short setup times

- Fast production of small parts with tight tolerances

- Saves time and money by combining multiple operations

- Long run lengths

Progressive die stamping offers an efficient and cost-effective method for producing parts in large volumes, making it a great choice for industry applications such as:

- Healthcare

- Mining

- Food and beverage

- Appliances

- Electronics

- Automotive

- Aerospace

- And more

Progressive Die Stamping Process

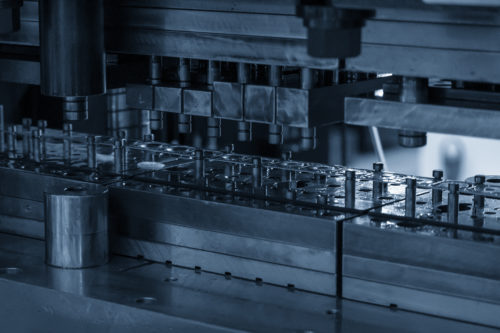

Progressive die stamping uses a type of tooling called a progressive die, which contains multiple stamping stations to carry out simultaneous operations on a sheet metal strip. By combining all the necessary tools into one die set, progressive die stamping is a great solution for high-volume production runs.

To begin the process, the die is placed into the stamping press. At Hudson Technologies, our straight side progressive presses feature a 60 to 500 ton capacity. The die opens as the stamping press moves up and closes as the stamping press moves down. While the die is open, the metal moves through the die, being precisely fed into the die with each press stroke.

When the die closes, it performs its work on the metal, which can include coining, bending, cutting, embossing, and more. Once the metal has moved through each station, the finished part is ejected from the die.

When to Use Progressive Die Stamping vs. Traditional Metal Stamping

When choosing between progressive die stamping and traditional metal stamping methods such as stage tooling and transfer press tooling, it’s important to consider factors such as cost, production volume, and lead time.

Cost

When considering cost, it’s important to think about tooling setup costs as well as per-piece cost. Stage tooling boasts lower setup costs but has the highest per-piece cost. Progressive die and transfer press tooling have higher setup costs compared to stage tooling but offer lower per piece costs.

Production Volume

Progressive die stamping is specifically designed for high volume production, typically exceeding 50,000 pieces per year. While transfer press tooling is also good for high volume production, it differs in that the part is separated from the metal strip during the first operation. Stage tooling, on the other hand, is ideal for small, low-volume production runs of less than 50,000 pieces per year.

Lead Time

When considering the needs of your project, it’s important to think of project timelines to determine which method is best. While stage tooling features a relatively slow fabrication speed, progressive die and transfer press tooling offer medium to fast production speeds.

Progressive Die Stamping Services from Hudson Technologies

If you determine that progressive die stamping is the best manufacturing method for your project, let the experts at Hudson Technologies help. We offer custom progressive die-stamped components as well as progressive die tool manufacturing. With over 80 years of experience, we have the necessary equipment and knowledge to meet your progressive die stamping needs. To learn more, visit our capabilities and tooling pages or download our Turnkey Solutions Ebook. You can also contact us or request a quote to get started.

Leave a Reply