Tips for Finding and Switching to a Better Deep Drawn Stamping Partner

Leave a CommentDeep drawn stamping is a metal stamping method used to create components that are deeper than they are wide. It is suitable for producing hollow parts and products that lightweight and seamless without sacrificing strength or stability. However, manufacturers must have the right knowledge, skills, and tools to form them successfully.

The following article outlines some of the things to look for in an ideal deep drawn component manufacturer. Additionally, it discusses how to switch suppliers if your current manufacturing partner does not meet your needs.

Importance of Deep Drawn Components

Deep drawn components are found in devices and equipment for a wide range of industries, such as:

Housings, shields, and battery casings for implantable medical devices

- Components for semiconductor manufacturing equipment

- Metal diaphragms for isolating enclosures in fluid systems, eliminating minor pressure changes in pressure sensor applications, converting movement into computer-readable communications, and/or protecting against overpressure

Housings and casings for batteries

- Instrument housings for sensitive equipment

- Connectors and couplings for electronic equipment

Given the important role deep drawn components play in many industrial applications and processes, it is essential to partner with an experienced and knowledgeable deep drawn stamping company to ensure the parts and products you need function and perform as intended.

Deep Drawn Component Supplier Selection Considerations

There are many factors to consider when choosing a deep drawn component manufacturer for a project. Some of the key considerations to keep in mind include:

Manufacturing Capabilities

Your deep drawn component supplier should have the skills and tools to accommodate your manufacturing needs with regard to material, design, and production volume and produce components that fully meet your specifications and standards. Additionally, if you’re looking for a long-term partnership, they should be able to adjust their operations to match increasing or decreasing demand.

Quality Control Policies and Procedures

One way of determining whether a deep drawn supplier is right for your project is to review their quality control policies and procedures. They should have quality standards that align with your own and the equipment and processes in place to ensure your components meet them.

Competitive and Innovative Drive

The manufacturing sector is highly competitive. Companies must be willing to invest in new technologies and technologies to ensure they can keep up with current demand and provide customers with the best possible products and services.

Customer Service

Your manufacturing partner should understand your needs. Additionally, they should be open to working with you to develop a manufacturing solution that fits them.

Company Reputation

Avoid working with companies with a bad reputation. While you should take negative customer reviews with a grain of salt, they can be indicative of potential issues with the company’s products and/or services.

Certifications

Switching Deep Drawn Stamping Partners

If your current deep drawn stamping supplier does not match what you’re looking for in a manufacturing partner, you should consider switching to one that better suits your needs. Once you’ve decided on a new partner, you should keep in the following tips in mind to ensure a smooth transition:

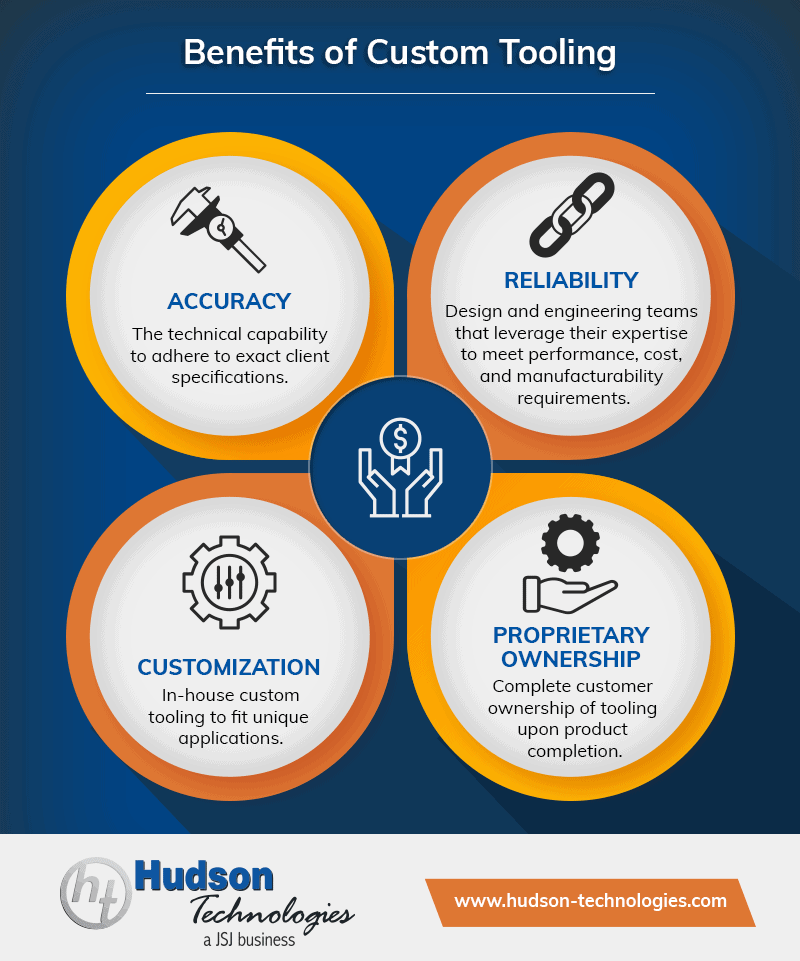

- Confirm whether you or your current partner owns your tools. If you do not own the tools, you will need to budget for the production of new tooling.

- Verify that your new partner has a thorough understanding of your material needs, tolerance requirements, and desired applications. If they do not, you should communicate with one of their representatives or consider other options.

- Ensure your current and future projects will be finished on time. If you have active projects with your current partner, make sure you finish them. Before switching completely to the new partner, perform a test run to verify they can finish your projects.

- Consider reshoring, nearshoring, or diversifying to multiple suppliers. These partnerships allow you to establish a more resilient supply chain. Read more about reshoring here.

Deep Drawn Stamping and Metal Drawing From Hudson Technologies

At Hudson Technologies, we’ve provided custom deep drawn metal parts and products for over 80 years. This experience, combined with our broad range of manufacturing capabilities and highly skilled team, allows us to produce precise, complex, and/or high-performance components for some of the most demanding customer applications.

For more information on our metal stamping services, visit our Capabilities page or download our eBook. To discuss your project requirements with one of our experts, contact us or request a quote today.

Housings, shields, and battery casings for

Housings, shields, and battery casings for  Housings and casings for batteries

Housings and casings for batteries

Wall thickness

Wall thickness Laser cutting. Laser cutting is ideal for precision designs with tolerances up to +/-0.005″.

Laser cutting. Laser cutting is ideal for precision designs with tolerances up to +/-0.005″.

The history of titanium stretches way back to 1790s England, but it didn’t enter the manufacturing scene until the early 1900s. Titanium is the ninth most abundant element in the earth’s crust, and it exists in sphene, rutile, and related minerals. As strong as steel but only about half as heavy, titanium alloys are used extensively in the aerospace and automotive industries, not only for their light weight and ultimate tensile strength, but also because titanium is durable and not susceptible to corrosion. Titanium resists chemical reactions with chloride solutions and many types of acids. This versatile metal is also used for bone setting, artificial hips, and other medical implants for the human body.

The history of titanium stretches way back to 1790s England, but it didn’t enter the manufacturing scene until the early 1900s. Titanium is the ninth most abundant element in the earth’s crust, and it exists in sphene, rutile, and related minerals. As strong as steel but only about half as heavy, titanium alloys are used extensively in the aerospace and automotive industries, not only for their light weight and ultimate tensile strength, but also because titanium is durable and not susceptible to corrosion. Titanium resists chemical reactions with chloride solutions and many types of acids. This versatile metal is also used for bone setting, artificial hips, and other medical implants for the human body.