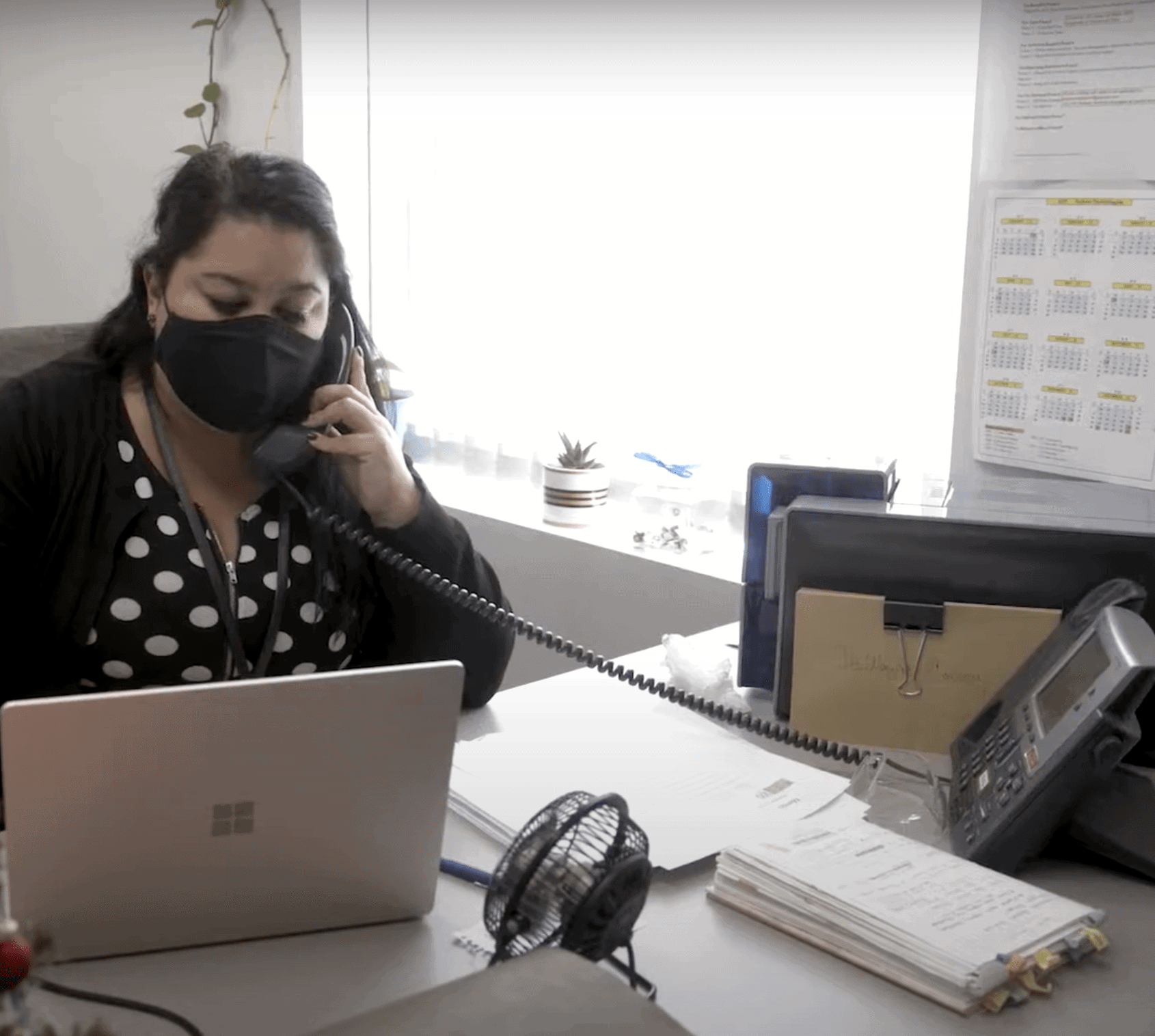

Purchase Order Received

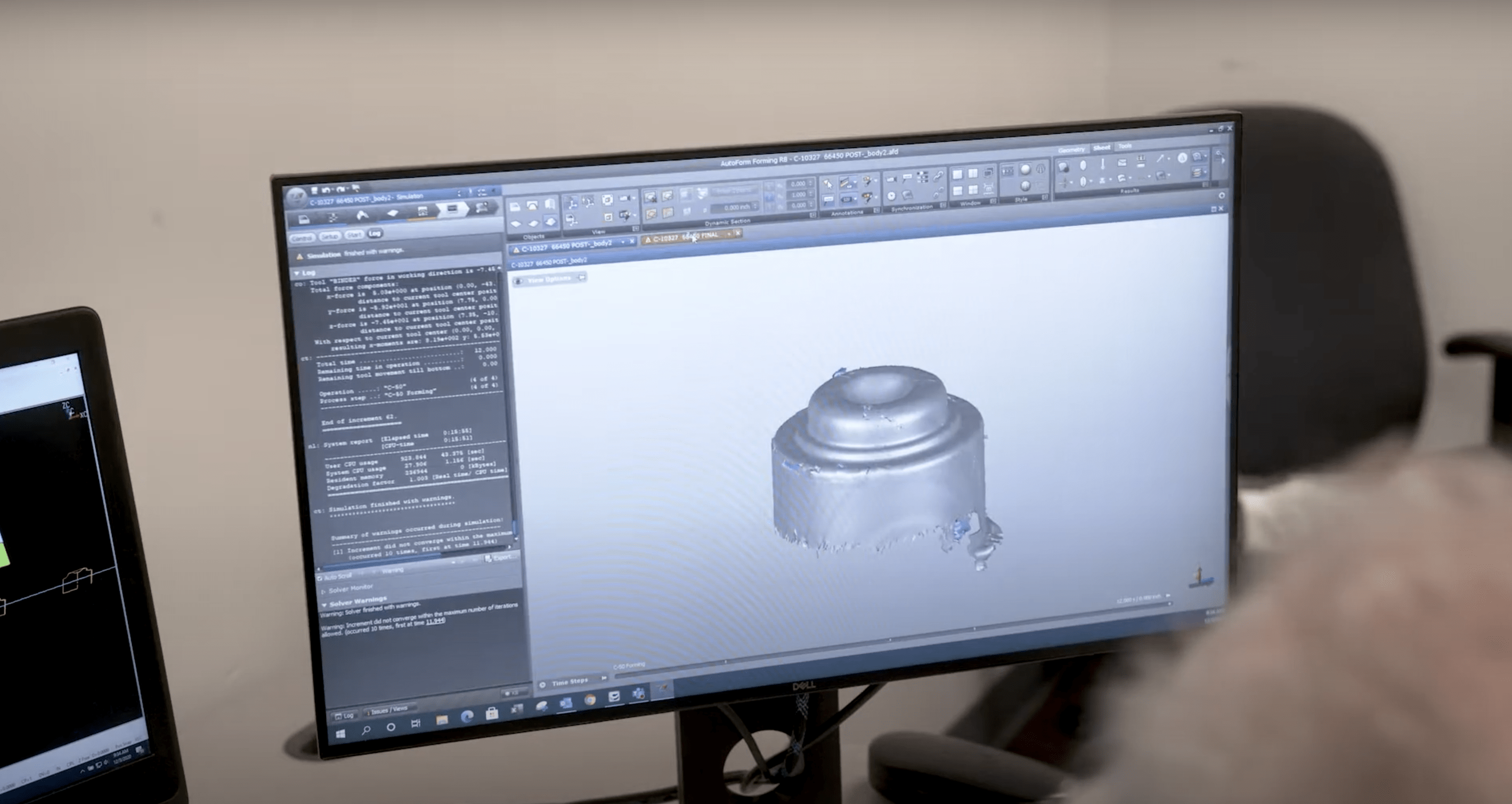

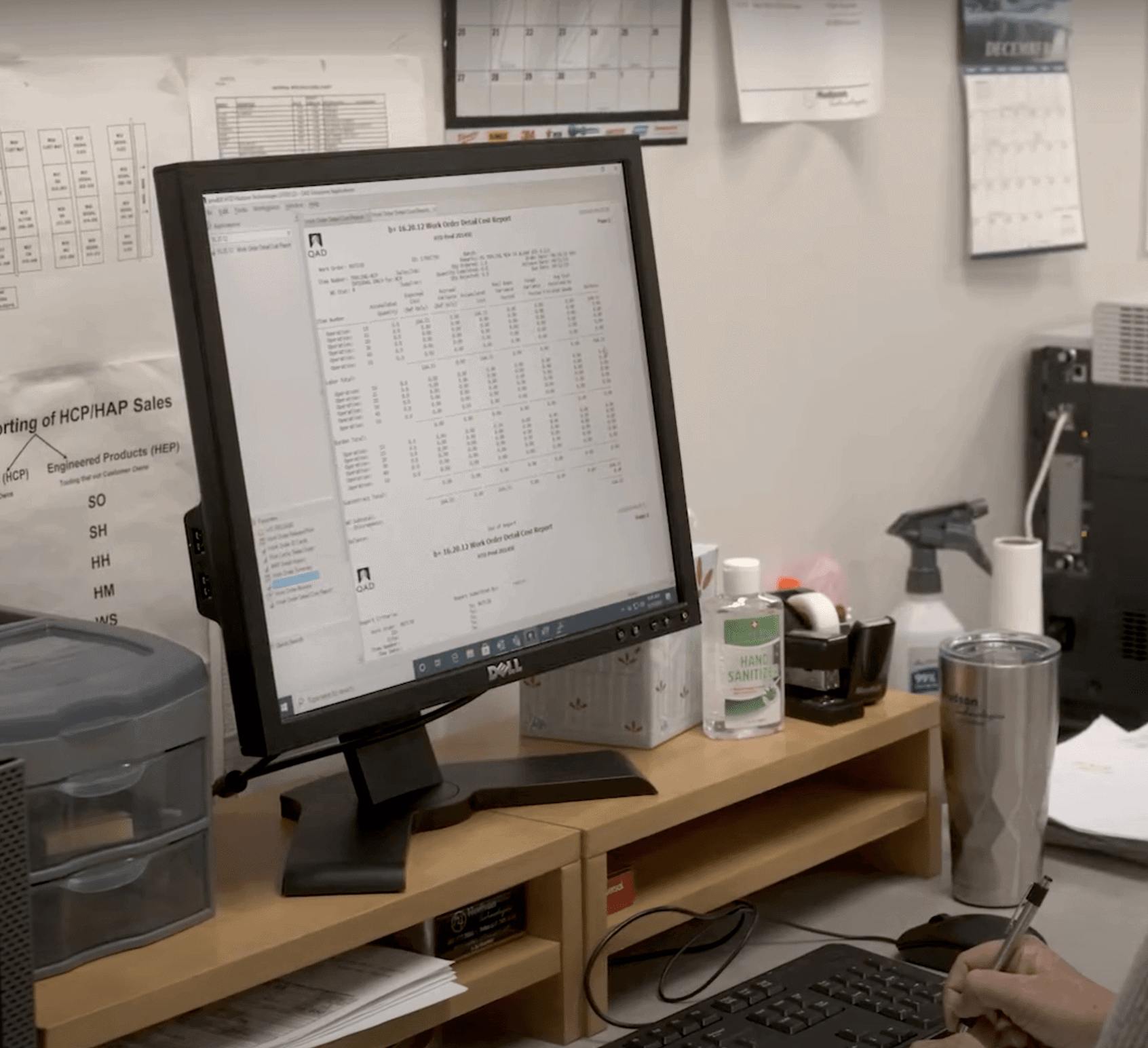

When a purchase order is received over the phone or from one of our online forms, our Customer Care team enters it into the system. From there, Production Control schedules the production of the project, including raw material scheduling and production time.