At Hudson Technologies, we offer a wide range of deep draw capabilities to produce highly customized, cost-effective metal parts for clients across all types of industries. With an eye on innovation and environmental stewardship, we are particularly proud to offer deep draw processes that produce far less material waste than most other machined parts methods.

Our company is AS9100D certified. We work tirelessly to ensure we stay ahead of the curve on all quality control processes and innovations. Our certifications, capabilities, facility, machinery, and secondary services grant us the ability to deliver high quality results for all of our customers.

Deep Drawn Manufacturing Services

At Hudson Technologies, we are proud to offer a range of high-quality deep drawn manufacturing services.

Manufacturing Processes

Our manufacturing processes and stamping services include:

- Shallow draw stamping

- Deep draw stamping

- Metal stamping

- Progressive die tooling

- Transfer press tooling

- Metal to rubber and metal to metal tooling for diaphragms

- Custom tooling to meet your exact specifications.

Finishing Processes

Our finishing options include:

- Aqueous cleaning, deburring, heat treating, and passivation.

- Anodizing, polishing, painting, powder coating, bead blasting, and plating

- Modifications, including piercing, extruding, bulging, coining, tapping, and machining.

- Resistance spot welding, TIG welding, laser welding, and brazing to MIL specifications.

- Assembly of components and brackets to deep drawn enclosures

- PEM®, stud, and standoff insertions

Design/Quality

Our design and quality services include:

- Engineering design assistance; finite element analysis (FEA); product design and metal forming simulation.

- Program management; trade compliance

- Lean; Six Sigma

- Smart Scope (optics, laser, touch probe) and metallurgical analysis (cold and hot mount)

Hudson Technologies offers expert assistance to help you choose the correct manufacturing process for your needs. Our custom services ensure that your process is suited to your exact specifications.

Our Manufacturing Facility and Machinery

Our facility houses a wide range of manufacturing equipment and machinery.

Deep Drawn Manufacturing Equipment and Capacity

Hudson Technologies’ state-of-the-art facility contains over 130 forming presses, all fully modernized and ready to handle projects of all kinds, no matter how complex. Our clients include small and large businesses, with projects ranging from prototype to high-volume (1 to 5,000,000 pieces).

We house an extensive array of state-of-the-art equipment in our 115,000-square-foot manufacturing facility. Hudson Technologies makes use of several types of presses with tonnages ranging from 1 to 500 tons, including:

- Double action mechanical

- Hydraulic

- OBI (Open Back Inclined)

- Pneumatic

- Servo (plus CNC cushion)

- Transfer deep drawing press

Tool Room Metalworking Machinery

Equipped with a wide range of top-quality machinery, our tool room allows the team at Hudson to provide reliable services that support our deep-drawn metal forming processes. Some of our tool room equipment includes:

- CNC mills and lathes up to 30″ swing

- Bridgeport milling machines

- Wire EDM (electrical discharge machines)

- Wire, sinker, and hole puncher

- Surface grinders

- Modification Capabilities

Customization Machinery

The team at Hudson is also committed to providing all clients with complete customization options, allowing you to easily meet the specific demands of your application. The following equipment and capabilities allow for easy modifications to metal parts:

- 5-axis laser

- Robotic finishing machine

- Spot welders

- Multiple trimming methods

- Lathes

- Spinner

- Vibratory tumblers

Finishing Machinery

In addition to our primary machining services, Hudson Technologies offers various finishing and other value-added services to ensure clients receive a finalized end product that meets all necessary specifications and requirements.

Custom & Standard Capabilities and Specifications

Hudson Technologies works with a variety of materials, sizes, and shapes to deliver standard and custom tooling based on your specifications.

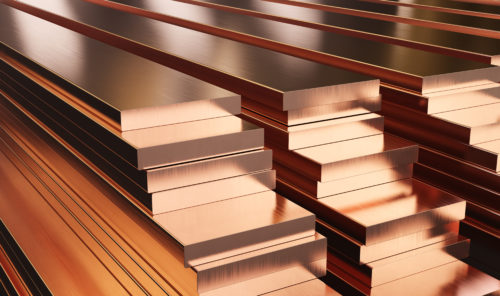

Materials

We have experience working with a range of materials, including:

- Aluminum

- Stainless steel

- Cold-rolled steel

- Copper

- Brass

- Nickel

- Nickel silver

- Cupro nickel

- HY-MU 80

- Titanium

- Monel®

- Hastelloy®

- Kovar®

- Inconel®

Our experts consider factors such as tensile strength, ductility, weldability, and machinability to determine which material will produce the best results while meeting customer specifications.

Sizes and Shapes

Hudson Technologies can produce parts of any shape to suit a wide range of applications and needs — from standard round, square, and rectangular to complex and asymmetrical geometries, in dimensions from 1/8 inch (3.1 mm) to 12 inches (305 mm) in diameter and up to 12 inches long, using material between 0.002 inch (0.05 mm) and 0.187 inch (4.75 mm) thick. We can produce metal diaphragms, flat or corrugated, in diameters ranging from 0.2 inch (5.08 mm) to 18 inches (457.2 mm) and in thicknesses from 0.001 inch (0.025 mm) to 0.018 inch (0.457 mm).

Supply Chain Services

At Hudson Technologies, we offer a selection of supply chain services to improve our customers’ manufacturing processes. Our Kanban services deliver lean manufacturing schedules along with stocking programs. Our expertise includes logistics services, parcel less-than-truckload (LTL) services, and export services. When our customers take advantage of our custom tooling, we can keep it in-house for expedited restocking. We can also re-use custom tooling to deliver future runs of production at a lower cost.

Design, Quality, and Cleanliness

The team at Hudson is deeply proud of our service offerings, and we’re constantly working to improve and innovate all processes and equipment to better serve our customers. Some of our other unique offerings and facility features include:

- Pick and place robotics

- Automated part loading, unloading, packaging

- Visual scheduling system

- Coil slitters (for raw material)

- Environmentally friendly lubricants

- Digital (LED) lighting throughout facility

- Tool storage management system

At Hudson Technologies, we deliver consistent results with our quality control and production services such as optical measuring systems, optical microscope inspection systems, CMM, automated SPC data collection, and in-line automatic optical inspection.

Our commitment to quality is backed by the certifications that we hold, including Reach and RoHS Compliance, Conflict Minerals, California Prop 65 Compliance, and ASD9100 Certification.

Our seamless solutions guide is available to help you learn more about each of the products we offer at Hudson Technologies.

Case Studies

Hudson Technologies meets the needs of diverse industries with solutions for high-volume orders, energy storage, and much more. The following case studies illustrate our deep drawn stamping capabilities in action.

High-Volume Components

When a leading innovator of electronic components reached out to us for assistance meeting the growing demand for their pressure sensor diaphragms, Hudson developed a highly effective and cost-saving solution. Our first course of action was to work alongside the client’s engineering team to modify the existing component design for manufacturability and cost-effectiveness.

We developed a multi-action tool capable of producing pressure sensor diaphragms at high speeds. After ensuring there was no sacrifice in quality or build consistency, we moved to the next step and arranged an agreement with our trusted raw materials suppliers. This long-term arrangement allowed us to lower material costs, minimize variation, and reduce lead times. We met the client’s strict price requirements and even submitted initial qualification samples ahead of the deadline. We currently manufacture millions of pressure sensor diaphragms for this client annually.

Enclosure for Energy Storage and Power Grid Technology

Energy power grid management company Ambri asked Hudson to develop an enclosure for a new energy storage application. The enclosure needed to withstand years of very high heat, thermal cycling, and corrosive chemical exposure. After a careful analysis of the application’s requirements, our team selected stainless steel for its durability and worked alongside Ambri to develop a thick-walled, custom enclosure.

Throughout the entire process, our team delivered weekly updates on the build progress, easily adapted to changing design requirements, and honored our commitment to on-time delivery. The resulting enclosure met all of Ambri’s high-performance testing requirements, and we are currently prototyping a second-generation enclosure for this client with even greater capacity.

Benefits

Deep drawn stamping is the most effective method of producing unconventional components that feature difficult geometries. It’s also ideal for products that require water-tight or air-tight enclosures. Deep drawn components feature numerous beneficial qualities, such as a combination of significant strength with minimal weight.

Some other key benefits of deep drawn stamping as a fabrication method include:

- Improved cycle times: Deep drawn stamping’s rapid cycle times are ideal for large-scale production needs, since draw speeds are only limited by the material’s required contact velocity. When multiple draws are required to produce the finished draw, they can be performed simultaneously, which optimizes cycle times.

- Material versatility: The deep drawing process is suitable for a wide range of metals. The most commonly used options include stainless steel, mild steel, brass, copper, and aluminum. Hudson can help you select the best material for your application.

- Decreased tooling costs: In addition to the productivity savings, deep drawn stamping also results in significantly less tooling costs. In most applications, just one set of simple carbide or tool steel dies is needed. These durable and renewable materials lower the need for costly re-tooling.

- Exceptional strength: Unlike other fabrication methods, rolled metals feature an elongated and cohesive grain structure. The deep drawing process facilitates an uninterrupted structure that produces a remarkably strong finished product.

- Seamless parts: Deep drawn tube or can shapes have no joints. This makes them ideal for applications that require water or gas-tight seals.

- High accuracy and repeatability: Since the deep drawn stamping process is highly repeatable, once set, it can produce hundreds of thousands of parts that fall within a tight tolerance range.

Parts Made From Deep Drawn Stamping

Deep drawn stamping is an important process for many industrial applications. Some of the components it creates include:

- Metal enclosures and covers

- Metal and foil diaphragms

- Battery enclosures

- Semiconductor machinery components

- Medical device housings

- Shields and half-shells

- Stamped and machined lids, covers, and headers

- Capacitor components

- Metal bellows

If you don’t see the component you’re looking for in our catalog of nearly 15,000 shapes and sizes, our team is happy to help you develop a cost-effective custom design that meets all of your performance requirements.

Choosing a Deep Drawn Manufacturing Partner

When choosing a deep draw manufacturer to partner with, it’s important to keep a few critical factors in mind to ensure you get the highest-quality parts possible, at a fair price. Consider the following tips during your search:

- Manufacturer’s experience. Although deep draw manufacturing has existed for over 140 years, it’s still a complex method, requiring a great deal of expertise. Be sure to partner with a knowledgeable, experienced company that can provide examples of past work and answer specific questions about their technique, quality control program, and quote breakdown.

- Vertical integration. Look for manufacturers that are vertically integrated, that can offer initial design assistance to lower cost. Design and build the tooling in house and manufacture the initial samples through full production volumes under one roof.

Partner with Hudson Technologies

As an industry-leading manufacturer of deep drawn metal enclosures, Hudson Technologies is proud to offer our clients a wide range of machining and finishing services with stringent quality control to back them up. In addition to metal enclosures and cases, we also specialize in stampings, including metal diaphragms.

Whether you need assistance with deep drawing, sampling, or designing, Hudson is here to help. Working on a high-volume-production project or need help with a design? Contact us today and an in-house metal forming expert will be in touch.